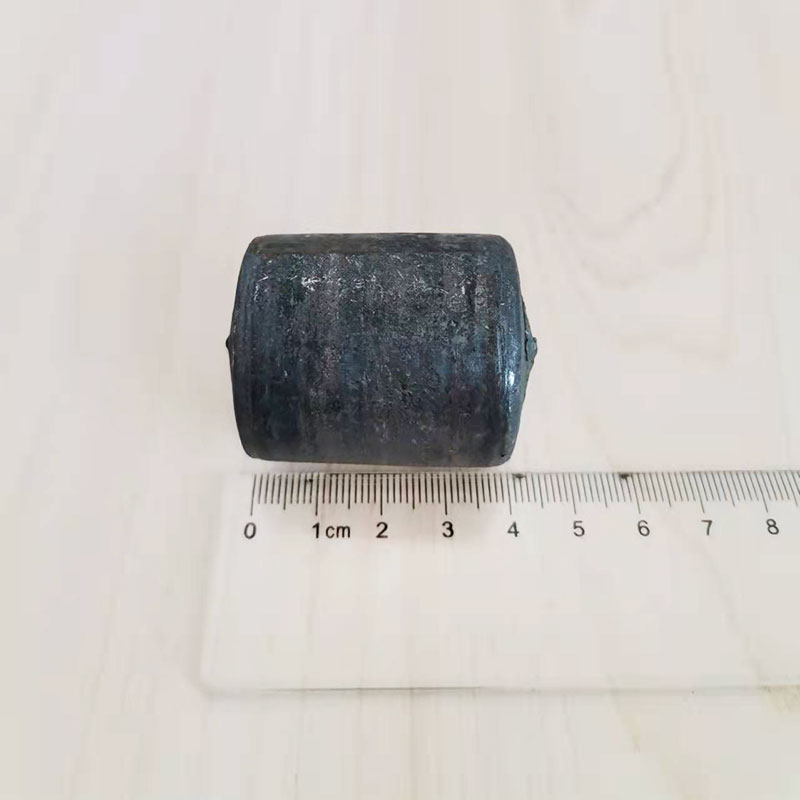

Grinding media consumption is an important factor to consider when processing iron ore in a ball mill. The grinding media used are typically steel or iron balls, and they come in various sizes and shapes depending on the specific application. The consumption of grinding media is a significant cost for any mining operation, and optimizing this cost is crucial to the operation's profitability.

The type of grinding media used can also affect the performance of the ball mill. Natural or manufactured non-metallic media, such as ceramic or silica beads, are sometimes used, but these tend to be more expensive than steel or iron balls. The size and quantity of grinding media used also affects the efficiency of the grinding process, as larger balls tend to grind the ore more effectively.

Corrosion is another factor to consider when choosing grinding media for iron ore processing. The high acidity and abrasive nature of the ore can cause significant degradation of metal media over time, leading to increased consumption and reduced efficiency. Therefore, some mining companies are now using non-metallic media, such as ceramics, which are resistant to corrosion and have a longer lifespan.

In conclusion, the consumption of grinding media in ball mills for iron ore processing is a significant cost for mining operations, and optimizing this cost is vital for profitability. Factors such as the type and size of grinding media used, as well as potential corrosion, should be carefully considered when choosing the optimal grinding media for a specific application. Zwell Steel Balls are an excellent option for iron ore processing, as they offer high hardness and wear resistance, as well as a reduced rate of consumption.